Integrating an intelligence remote monitor diagnostic system for your ship network system.

As ships become increasingly equipped with advanced electronic systems, digitalization is transforming vessel operations and offering significant advantages in monitoring and servicing. However, when operational data is isolated within individual devices, gaining a holistic understanding of the ship’s generation, distribution, and propulsion systems becomes difficult.

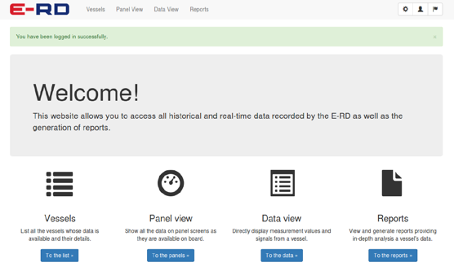

Our E-Remote Diagnostics (E-RD®) system solves this challenge by providing centralized, real-time access to critical operational parameters across power generation, propulsion, and electrical distribution systems.

Designed with a modular architecture, the E-RD® allows for the seamless integration of additional onboard systems with minimal effort. Each new connected system expands the analytical capabilities, enabling engineers to correlate cross-system data and continuously optimize vessel performance for economic efficiency and environmental compliance.

Our expert service team provides continuous support to onboard crews, addressing technical issues and operational questions as they arise. Through real-time diagnostics and full visibility into system health, we maintain awareness of each ship’s technical condition.

Automatically generated reports and performance evaluations enable objective comparisons of vessels in technical, operational, and economic terms. Data can be visualized in various formats, from routine email summaries to an interactive, pan-European vessel map that displays real-time ship locations and statuses for easy, fleet-wide tracking and benchmarking.

Data-driven operational and technical optimisation of vessel performance

Operational improvements, starting with the way the crew works, through to technical improvements of individual systems on board, can be developed from the data obtained and then implemented on individual ships. The E-RD then enables a direct comparison of ships to be made very quickly, allowing conclusions to be drawn as to whether the changes are having the desired effect.

A detailed analysis can be carried out immediately after a claim becomes known. A quick response through telephone support is guaranteed thanks to the real time troubleshooting with detail data and curves for the whole system. Many on-site root cause analysis from different companies are avoided, which saves a lot of time and money.

In preparation for regular maintenance and repair work on ships, E-RD analyzes of components and system parts can provide information about the condition. This makes it possible to carry out the targeted coordination of operations with the corresponding spare parts from different companies in advance. Furthermore, on-site assignments with spare parts can be organized quickly. The E-RD supports the person on site on a ship, because the E-RD can check if any error is still there easily.

During new ship construction and in particular during commissioning, the E-RD is able to record and display the performance of the propulsion system. A detailed target and actual analysis of the performance parameters of the system components can be carried out.

For the warranty period, these analyzes are important basic information for shipyards when dealing with the manufacturers of the components.

Key benefit to use the E-RD service

- Detail data based root cause analysis

- Reduce unnecessary onsite travel

- Preventive maintenance

- Fast organize of spare parts

- Future system optimization

Our service offering

E-RD is an ideal solution for the shipyard to know the system behavior.

It is an ideal solution for the ship owner to see and improve the system performance as well as to do the avoid system error in advance.

It is an ideal for the component manufactures to know the limitation of their products during the integration in the ship.

Send us your questions and demands.

Get in touch with our marine engineering team. Our experts are happy to discuss your demands and ideas finding the perfect solution.